An article by IMOA’s Technical Director, Dr Nicole Kinsman

Molybdenum containing stainless steels are widely used to line indoor and outdoor swimming pools across Europe. The first stainless steel linings have been installed around 1970 in Austria. Today, there are over 5000 installations in Europe, mainly in Austria, Germany and Switzerland, but also in Belgium, France, Italy, Czech Republic and Slovakia among others.

In the early years the molybdenum-free 1.4301 (Type 304, UNS S30400) stainless steel has been used for outdoor pools and the 2% molybdenum containing 1.4404 (Type 316L, UNS S31603) stainless steel for the harsher conditions in indoor pools. However, for many years now 1.4404 stainless steel is the standard material for indoor and outdoor applications because of its increased corrosion resistance in chloride containing waters. Stainless steel grades with higher molybdenum content are necessary in swimming pools with more aggressive waters, such as hot spring, brine or seawater pools. Stainless steel can be used for new installations and to restore older pools. Both applications are about equally frequent.

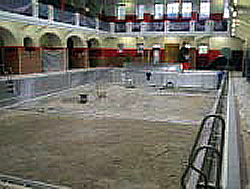

Figures 1, 2 and 3 show the installation of a stainless steel lining in an indoor pool in Vienna, Austria. The goal was the rehabilitation and modernization of the pool. The existing basin has been lined with a new stainless steel skin. This successful renovation project showcases the harmonic integration of a modern stainless steel pool into a grand historic structure. The weight of this stainless steel multipurpose pool is about thirteen metric tons. Berndorf Bäderbau in Berndorf, Austria is the industry leader in Europe and has built over 4000 installations. They have an annual consumption of about 2000 metric tons of stainless steel.