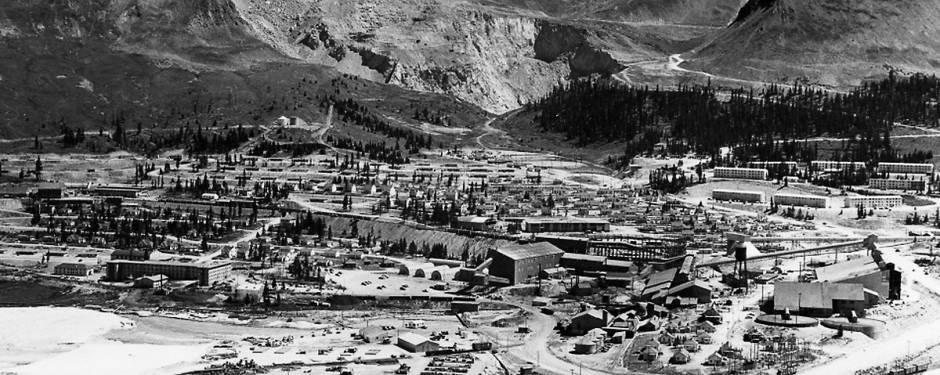

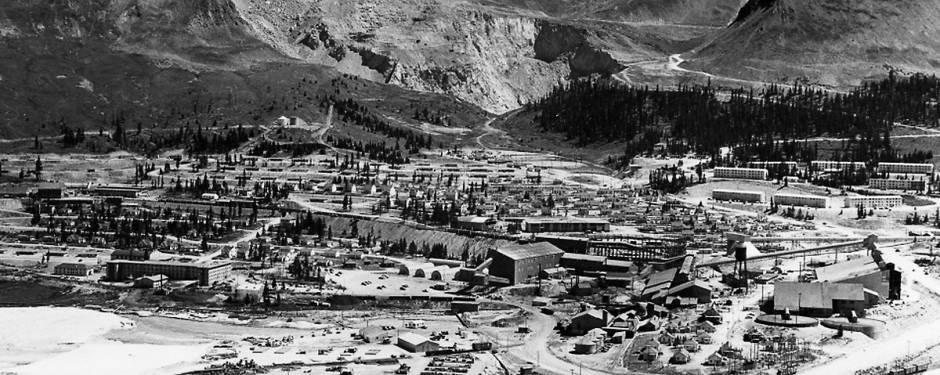

Historical mine site. © Climax Molybdenum

A brief history of molybdenum

Around 90 chemical elements are found in nature, including molybdenum, which occurs in compound minerals called molybdenite, wulfenite, and powellite. By far the most common of these is molybdenite, a greasy, silver-gray mineral that leaves a mark on paper. Molybdenite was known and used in ancient times, but it was unclear if it was just another ore of lead or graphite. The element’s challenging name comes from “molybdos”, meaning lead-like in ancient Greek.

The differentiating discovery

It wasn’t until the end of the 18th century that molybdenum was consistently distinguished from lead and graphite. In 1778, renowned chemist Carl Wilhelm Scheele decomposed a sample of molybdenite in hot nitric acid and determined it was a sulfide compound of an unidentified element. Three years later, another chemist, Peter Jacob Hjelm, isolated an impure form of what he named “molybdenum” for the molybdenite mineral ore where it occurs. Molybdenum was not used commercially for another 100 years, until metallurgists found it could harden steel in 1891.

Around the same time, Norwegian peasants discovered a rich deposit of molybdenite near Knaben in the south of Norway. They established molybdenum’s first commercial valuation at one pound of molybdenite for a pound of butter. Scientists began studying the ore in earnest and demand increased enough that two additional mines opened at Knaben in 1895.

Before molybdenum, tungsten was a key element used to harden steel, critical for tank bodies and other defense machines. World War I squeezed the global tungsten supply, leading to its substitution with molybdenum. Demand soared. Now miners at Knaben were trading a pound of molybdenum for three pounds of butter.

From obscurity to a multitude of uses

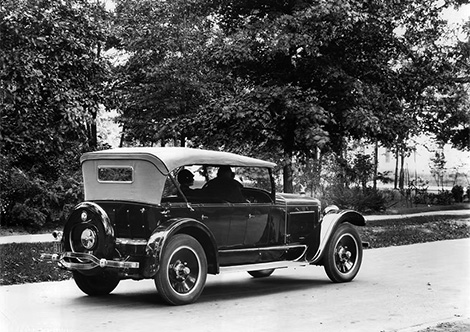

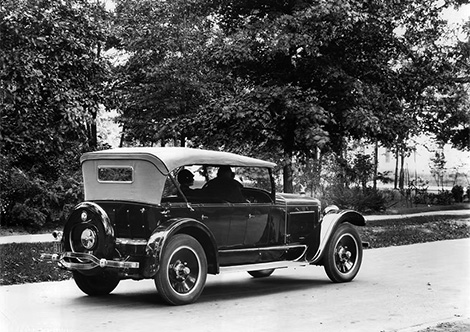

After the war ended, molybdenum moved back into irrelevance. Another early mine, Climax in the US, donated product to steel companies willing to experiment with it, but the conservative industry was not interested. However, a famous automotive engineer, C.H. Wills, ordered quantity of the cheap wartime alloy to make an ultra-durable luxury car. In 1921, the “Gray Goose” was released, with every component of the vehicle subject to stress made from a molybdenum-containing steel alloy. These cars served as an advertisement for the element’s ability to make steel more durable. By the mid-1920s, major automakers and steelmakers began ordering molybdenum in quantity, and governments and industry agencies recognized it as a standard industrial alloying element.

The Wills Sainte Claire “Gray Goose”, produced from 1921 to 1926, won many cross-country races, thanks to its molybdenum-containing construction materials. © Wills Sainte Claire Auto Museum

Following the Gray Goose’s success in the early 1920s, engineers expanded on molybdenum’s wartime role in aviation, where chromium-molybdenum steels were used in aircraft frames for their strength-to-weight advantages. Molybdenum’s ability to retain strength at high temperatures made it ideal for early aircraft engines.

Beginning in the early 1930s, molybdenum was alloyed into stainless steels, giving rise to Type 316, a grade with exceptional resistance to pitting and crevice corrosion. This new alloy was soon adopted in marine and chemical equipment as well as food processing. Meanwhile, in 1932 researchers identified that molybdenum naturally occurs in humans, plants, and animals, which eventually led to understanding its role as an essential trace nutrient for most living organisms and to other uses, including fertilizer additives.

After World War II, molybdenum became vital in many types of carbon steels, including tool and high-speed steels, and high-strength-low-alloy (HSLA) steels. Molybdenum-bearing stainless steels also gradually became standard in nuclear power and pharmaceutical processing – anywhere corrosion resistance was essential.

By the 1980s, molybdenum-bearing steels were indispensable in superalloys for jet engines and gas turbines, in corrosion-resistant grades for oil, gas, and chemical processing, and in catalysts used in cleaner fuel production. Molybdenum disulfide also gained wide use as a dry lubricant in aerospace and industrial machinery.

Today, molybdenum plays a growing role in wind turbines, solar thermal power plants, and ultra-high-strength steels for automotive safety and weight reduction. It also remains critical in oil country tubular goods (OCTG) and hydropower infrastructure. Though steel remains the largest market, applications continue to diversify, from molybdenum metal in lighting and semiconductors to Mo-99 isotopes in nuclear medicine. New discoveries involving molybdenum happen constantly – its greatest role may lie ahead!