Molybdenum and its applications

Stainless Steel Mechanically Applied Finishes:

Specification, Durability & Corrosion Performance

Finish terminology for standard mechanically abraded and buffed surfaces varies around the world as can the typical appearance, gloss (reflectivity) and surface roughness of a particular finish. For large projects where finish matching is critical, it is important to agree on a visual standard as well as acceptable surface roughness and gloss (reflectivity) tolerance ranges and other quantifiable characteristics before placing the order.

Surface roughness can have a tremendous influence on corrosion performance and dirt retention. Table 2 provides the results of a survey of North American and European surface finish providers and the roughness ranges associated with some of these finishes. IMOA has a Finish Specification webpage, which provides brochure and website links to more information on finishes, quantifying key characteristics, and corrosion performance.

Standard Polished or Linished Finishes

These “standard” finishes are the mechanically abraded and buffed finishes, which are defined by international standard specifications. The terms “polished” and “linished” are both used to describe these finishes in different parts of the world. Standards describe the production processes used to obtain them and the general appearance but not quantifiable characteristics. Images of these finishes can be found on SSINA’s website. ASTM does not distinguish between the fine wet and rougher dry versions of the No. 4 polish. JIS and Euronorm standards use No. 240 and 2K, respectively, to identify this finer polish.

Table 1: International standard cross reference

| ASTM A480 | Japan JIS | Euronorm EN 10088 |

|---|

| No. 3 |

No. 3 |

2G |

| No. 4 |

No. 4 |

2J |

|

|

No. 240 |

2K |

| No. 7 |

No. 7 |

2P |

| No. 8 |

|

2P |

Non-Standard Mechanical Finishes

These finishes are not described in international standard specifications. The generic terms for them have been used below. Variations on these finishes are also sold under trade names and are often aesthetically unique.

Hairline, Fine-line or Long Grain Polish

This finish has seemingly endless, very fine, linear polishing lines that are applied with non-metallic abrasive pads. It is usually smoother and more reflective than a wet polished ASTM No. 4, JIS No. 240 or EN 2K polish, which have short linear polishing lines on sheet or strip products. Small scratches can be repaired in the field with non-metallic pads of equivalent grit or roughness.

Highly Buffed Mirror Polishes

The ASTM A 480 No. 8 or EN 2P polishes have been abrasively polished and then buffed but remnants of the polishing lines are still visible under close examination. True mirror polishes are sold as Super No. 8, 9 and 10 (or some higher numbers) and are mechanically polished and then buffed. They are a higher quality finish than a buffed Bright Annealed (BA) mill finish. Determine what polishing media was used. Some low cost suppliers use iron oxide, which can contaminate the surface and cause corrosion. Applications range from decorative panels to bathroom mirrors.

Vibration or Fine Non-Directional Finish

This is a very fine, non-directional scratch pattern with either long or short scratches. It can be applied by hand or with computer controlled equipment programmed to obtain a high level of consistency. Fine stainless steel brushes or non-metallic pads are typically used to obtain the finish. It is usually quite smooth and capable of hiding light random accidental scratching. Variations in scratch length and density can produce substantial differences in appearance. This finish is less reflective than the fine linear finishes.

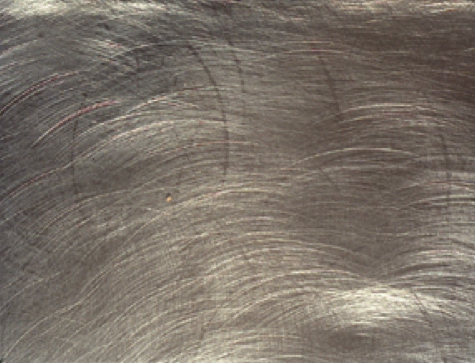

Coarse Non-Directional Finishes

These finishes also have a non-directional appearance, are applied using the same methods described under “Vibration Finish”, but coarser wire brushes or grinding wheels may be used. The rougher pattern can hide heavier random and deliberate scratching in high traffic areas. They are usually very rough finishes and not suitable for corrosive or high dirt accumulation areas unless there will be regular cleaning.

Many patterns can be created with grinding wheels or stainless steel wire brushes, ranging from controlled swirls to simulations of a field of grass. These finishes can also be applied by hand or with computer controlled equipment. A wide range of patterns can be created this way, but they are typically rough and not suitable for corrosive or high dirt accumulation areas, unless there will be regular thorough cleaning.

Table 2: Typical sheet and strip finish roughness ranges from North American and European stainless steel suppliers

| Designation | Ra, microns (micro-inches) |

|---|

| #3 |

0.25 – 1.10 (10.0 – 43.0) |

| #4 |

0.18 – 0.64 (7.0 – 25.0) |

| 6 |

0.30 – 0.46 (12.0 – 18.0) |

| 7 |

0.06 – 0.20 (2.4 – 8.0) |

| 8 |

0.02 – 0.10 (0.74 - 4.0) |

| Super No. 8 |

0.01 – 0.02 (0.4 - 0.8) |

| Hairline |

0.14 – 0.20 (5.5 - 8.0) |